2025

Month updates - May & June 2025

Month updates from May & June 2025 - what’s been going on around Sheffield Hackspace?

Month updates - March & April 2025

Month updates from March & April 2025 - what’s been going on around Sheffield Hackspace?

Dice Casting Workshop

Month updates - January & February 2025

Month updates from January & February 2025 - what’s been going on around Sheffield Hackspace?

Month updates - November & December 2024

Month updates from November & December 2024 - what’s been going on around Sheffield Hackspace?

2024

Learning how to build guitar effect pedals #1

I have been playing guitar since I was 15, but I never could make it a routine. This changed in 2020 when the plague hit and I discovered Yousician. The gamification of the experience gave my ADHD the dopamine hits I was craving. I was hooked.

Month updates - September & October 2024

Month updates from September & October 2024 - what’s been going on around Sheffield Hackspace?

3D printing a repair for my sellotape dispenser

Month updates - August 2024

Month updates from August 2024 - what’s been going on around Sheffield Hackspace?

Month updates - July 2024

Month updates from July 2024 - what’s been going on around Sheffield Hackspace?

A Visit to Liverpool MakeFest

alifeee and Nik volunteered at Liverpool MakeFest… this is what they found, thought, and found wonder about within!

Computer font making workshop

2020

Quick and simple charge protection board with 18650 holder

A short video demonstrating a quick and easy way to build a charge protection board for 3s (3 x 18650 batteries in series). 3 x 18650 in series will give you around 12v. The board will help protect the battery pack from overcharging, over-discharging, over-current and short circuit.

Order PCB with surface mount components in under 15 minutes with easyEDA circuit design

I’ve been research designing circuit boards design and tried a few different such as eagle, ki cad and came across easyEDA which is perfect for newbies like myself. Its simple to use, the SMC (Surface mount components) selection is all tied in. You can order a PCB and have all the component (well most of them) soldered at the manufacture JCL without you have to do any soldering at all! Take a look at the video below for a quick demo

Align holes in your project box without measuring – no special tools required.

In a previous post I described how to align holes without measuring. My original alignment tool was laser cut, but due to lockdown I’ve had to devise a simpler way to acheive the same accuracy using readily available materials – this time I use BluTac and an old milk carton.

Wemos D1 mini GPIO test board

Visualise Active Ports

Minecraft auto mouse spin wheel

When you are building creations in Minecraft, sometimes you need to have random blocks placed down from you hotbar. With this little program created with the help from Simon, (Thanks Simon), you now don’t have to manually spin your mouse wheel to achieve this.

Live recorded docker tutorial

A live docker tutorial for the Sheffield Hackspace. A run through through what is docker, benefits of docker, popular docker containers for Hackspace members (Node-Red, MQTT, Octoprint, Grafana, InfluxDB, ROS), running image as containers and how to develop using visual studio code docker plugin.

Perfectly aligned holes without measuring

How to cut a hole to mate up with what’s inside your project box.

2019

Brompton bag

I needed a new bag for my Brompton bike. All the bags were very expensive, £70 for the basic bags so I did what any maker would do and started on the journey to make my own bag. There was a few challenges:

I needed a new bag for my Brompton bike. All the bags were very expensive, £70 for the basic bags so I did what any maker would do and started on the journey to make my own bag. There was a few challenges:

1 . Find a way to connect the bag to the front carrier block securely.

- Find a cheaper bag that i could modify easily and thats water proof

- Work out if anything else was need, e.g. bag strengthening.

I started by look on thingiverse for 3D printed Brampton carrier block, its always a good place to start to see how other people have attacked the problem. I didn’t find anything. I set work to design one myself using fusion 360 – Matt SB gave me a helping hand to get started with as its the first functional 3d object I’ve printed. I came up with the item below after a few iterations printed on my Aldi 3D printer.

A Model Lighthouse

Designed and built at the Sheffield Hackspace using an arduino and bits and pieces of things that you might find lying around in your own home…

Rescue off-screen windows easily (Windows.10 and Linux.Mint)

When a program is moved off the main screen – maybe to a second monitor which is now no longer connected – you need a quick and easy way to move it to the current monitor. This is what I do –

2018

A wi-fi and touch controlled NeoPixel ring using the Wemos D1 Mini ESP8266 module.

Sheffield Hackspace install Lorawan gateway

Sheffield Hackspace has setup and installed a LoraWAN (The Things Network) gateway. LoraWAN is a new technology that enables small amounts of data to travel large distances with low power and the best bit of it is….its free!! This is being used by universities, corporations and hobbyist a like to transmit data such as air quality, traffic, temperature, gps informational ect. from battery (or wire) powered devices that last up to 10 years and more.

DreamPi and the Dreamcast

Getting a Dreamcast games console in 2018 is great but there are something that you can do as Sega has stopped supporting it for may a years now. This means that you can’t play some of the great games online. The following article will help you get the Dreamcast back online and playing the awesome games this short lived system has to offer.

A super simple way to copy files from a networked computer

Ok, so you’re wanting to extract files from your Raspberry Pi (or other networked computer) and you can’t be bothered to go find a USB flash drive (don’t feel guilty, I’ve been there too). How about you set up a temporary HTTP file server of the information and access it from any web browser on another computer? Impossible you say? Not quite apparently.

2017

How to download a complete website, including links between pages.

Quite often, you may download sections of a website, only to find downloading separate pages does not maintain the links between them.

Arduino Day 2017

Making a kit knife

Since moving into the Portland Works in January 2015 I have had a desire to learn more about knife making. Obviously there is a long tradition of knife making in Sheffield generally, and more specifically at the Portland Works https://www.sheffieldhackspace.org.uk/585 so it felt fitting to start exploring this new interest at the hackspace.

2016

Make a hedgehog house for your garden

We’re getting toward hedgehogs’ hibernation season, so Sarah built a hedgehog house for her garden, and wrote up her process for others to follow. It’s a fun weekend project; if you make one, we’d love to hear about it. Of course, we have all the tools you need in the hackspace, for all members to use. Call in to one of our open sessions to take a look.

Programming the ATtiny85 using an Arduino UNO

By Richard M Langner

Electromagnetic Field 2016

A great weekend was had by all as multiple members of SHH&M went down to Loseley Park for EMF2016. Our entrepid woodworker, AJ, went ahead of the rest of us to build the sink frames, back of the bar and multiple other items ahead of over 1400 people decending for a weekend of camping. However, as should be expected from a group of hackers and makers camping, electricity and high speed internet were essential amenities. We had our own Village, complete with flag, and took along some Go-Boxes and Bugs’s pancake engraver to show off (blog to follow!).

Bookcase with clock stand

One of my own projects this time: a bookcase with an upright to hold a favourite clock. I didn’t want to drive nails into my (rented, plasterboard) walls and can always use extra shelf space, so I came up with this as a woodworking project. I’m a complete beginner at woodworking, so I learned a lot making this and had a lot of help from other hackspace members. It’s not perfect, but it does its job and I still have all my fingers so I’m calling it a success. At least, until I start work on version 2…

A few recent snapshots

A few of the things we’ve been up to in the hackspace over the past week or two: Sewable arduinos (floras) and crochet, woodworking on the new lathe, silverwork on the jewellery bench, soldering up some electronics projects, painting the walls for our cellar expansion while planning the next builds, and lots of coding, writing and chatter.

Box making

Recently I thought that I would experiment with some new methods for box making. This particular box is made from pine, not exactly something you would use to make quality furniture with but it is really only a practise piece.

Hillsfest 2016

We had a good time at Hillsfest this year! Lots of friends and new faces with stalls in the Makers Dome, and we really enjoyed chatting with everyone who came up to make wollen bobbles (Thanks to Jo and Sarah for running that!), and ask about all the 3D printed, lasercut and otherwise member-built things we had on display.

A bit of jewellery repair

Inkscape for Beginners workshop

Nixie clock prototype

We won Sheffield Soup Funding for our expansion!

Homemade smoke machine liquid!

A quick experiment by one of our members, in preparation for making a gun that shoots smoke rings.

Deckchair building

A few lasercut pieces…

2015

Quadrant 3D Printer Cabinet

With the Hackspace having a collection of three different 3D printers and with them all being kept in one multi use workshop, it soon came apparent that we needed a way to keep the dust of of them all whiles also allowing us to gain easy access to them for maintenance. There was an ideal place in the workshop between the workbench and tool board where a cabinet would sit nicely.

Simply Crochet Robot

Mam Tor Kite Aerial Photography

Several members of the group attended Geeks in the Peeks recently (4th-6th September 2015). As part of this on the Saturday, we decided to take my Kite Aerial Photography rig to the top of Mam Tor to see if we could take some photos. I brought along my Raspberry Pi based system (A model A with a camera module, air pressure sensor, USB wifi card (for the web UI preview and start/stop/shutdown buttons) and LiPo battery) which takes images every 7 seconds, on average while airborne.

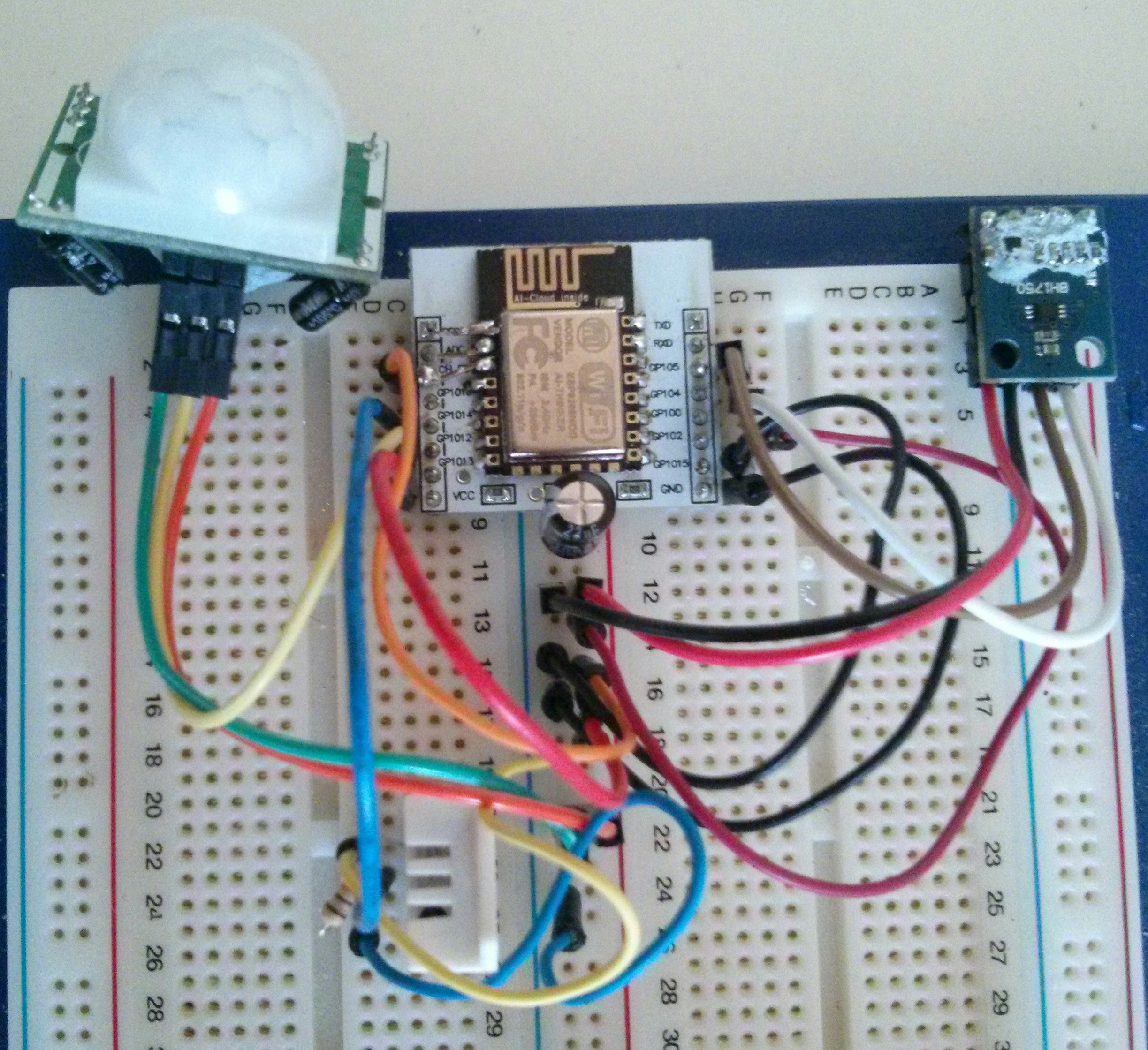

Indoor environment sensor with ESP8266

London Hackspace Visit

I have to apologise to the guys at the London Hackspace (LHS) in advance for this write up. I visited around a month or so ago and have only just got to writing it up. Whilst kicking around in London with a day to spare, at short notice, I contacted the London Hackspace and asked if I could come visit. Jasper replied pretty quickly and despite the horribly short notice was a very willing and helpful host. Many thanks then to Jasper.

A quick snapshot

Busy times here at SHH&M! A few snapshots of things our members have been working on recently in the hackspace:

Experimental Foods Day

Marvellous Marble Machines

Edinburgh Hacklab Visit

Whilst in Edinburgh for a conference we took some time out to drop in on the local hacking community and compare notes. Edinburgh Hacklab have been on the go for a while now and are on the second iteration of their own space, having moved from the other side of the city centre to Summerhall. Initially like SHH&M they started out meeting once a month in space shared with other community groups.

Circoflex kite

Arduino Day 2015 was great fun!

ATtiny 85/45/13 Programming Shield

Author: James Muirhead

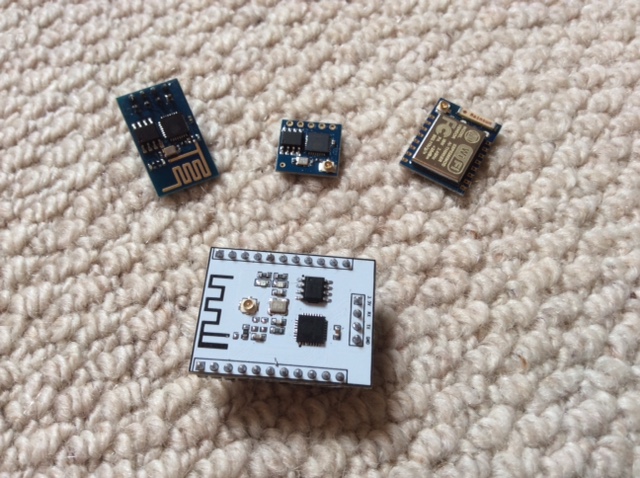

RFID access system using ESP8266-01

We Exist!

Machine sewing

A roof over our heads

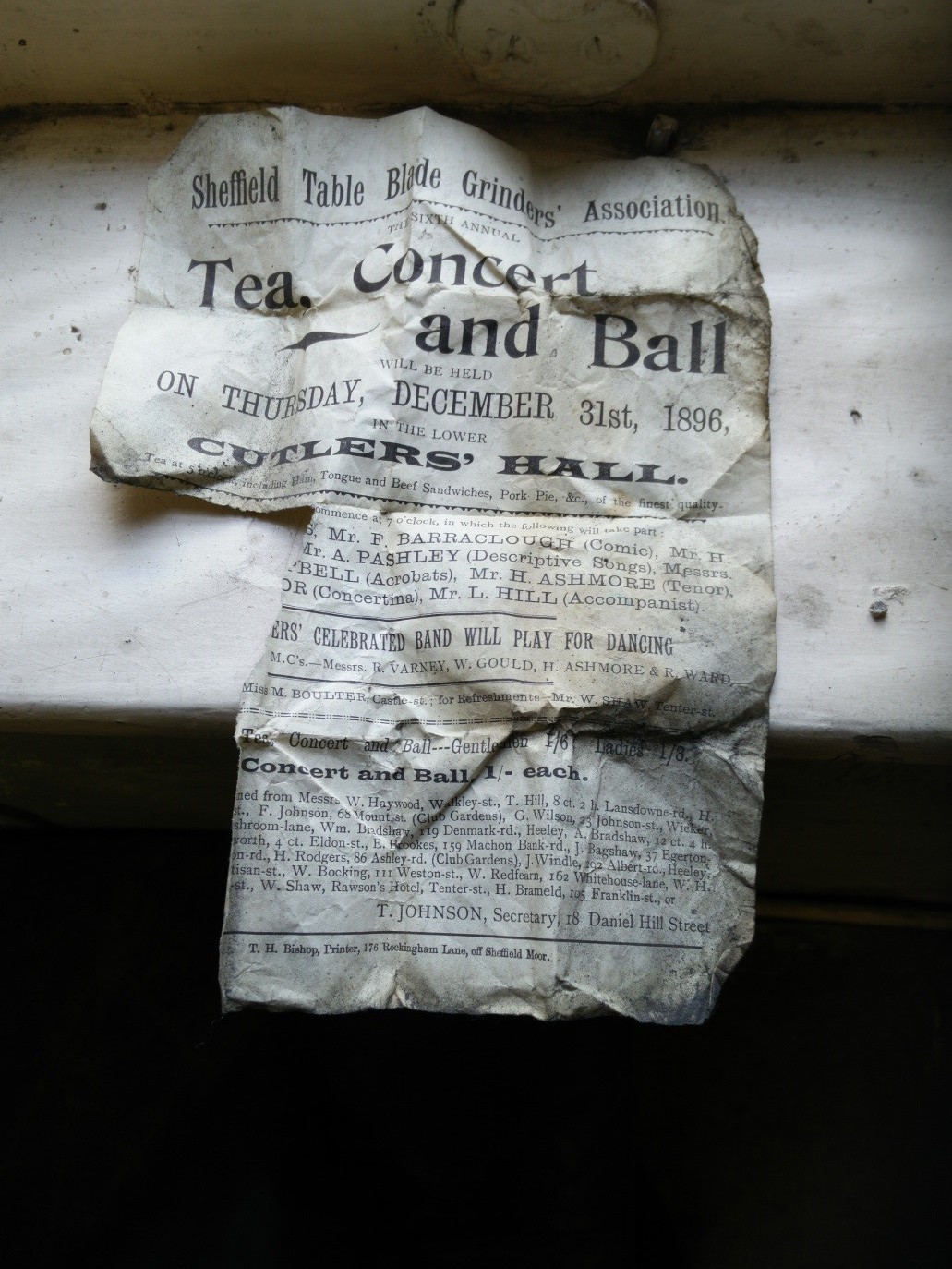

Insight to the 1890’s

An exciting find!

An exciting find while renovating the small room at our new HQ. Found in the ceiling were a collection of about 20 different knives and blades (finest Sheffield Steel of course!) wrapped in newspapers dating from 1890, 1885 and 1881! The Portland Works was home to Robert Mosley, the first manufacturer of stainless steel cutlery that carried our city’s name into kitchens and dining rooms across the world, and this looks like his work. Maybe SHH&M’s new home is one of his old workshops? After getting a lot of interest, we’ve passed them to the resident historian at Portland Works to make sure they’re properly preserved and put on display.

An exciting find while renovating the small room at our new HQ. Found in the ceiling were a collection of about 20 different knives and blades (finest Sheffield Steel of course!) wrapped in newspapers dating from 1890, 1885 and 1881! The Portland Works was home to Robert Mosley, the first manufacturer of stainless steel cutlery that carried our city’s name into kitchens and dining rooms across the world, and this looks like his work. Maybe SHH&M’s new home is one of his old workshops? After getting a lot of interest, we’ve passed them to the resident historian at Portland Works to make sure they’re properly preserved and put on display.

Hacking the space!

Retro IBM 12″ VGA monitor (8512) attached to a Raspberry Pi!

One of our members, James Muirhead, managed to get a classic IBM monitor working with his Raspberr pi! He says:

One of our members, James Muirhead, managed to get a classic IBM monitor working with his Raspberr pi! He says:

2014

Kite Arch

A post from the archives this week. We have a couple of members who’re interested in kites and kite photography, so we decided to try making some of our own. For a first project, a kite arch!

A post from the archives this week. We have a couple of members who’re interested in kites and kite photography, so we decided to try making some of our own. For a first project, a kite arch!

Our visit to Nottingham Hack Space

Last week as part of our research in to opening our own hackspace, one of our members contacted Space. Nottingham was one of the first hack spaces to pop up in the UK, it followed on from London. Arrangements were then made to go and visit. This was to gather as much information as possible related to running/setting up a Hack Space. They have a free open night every Wednesday open to the public.

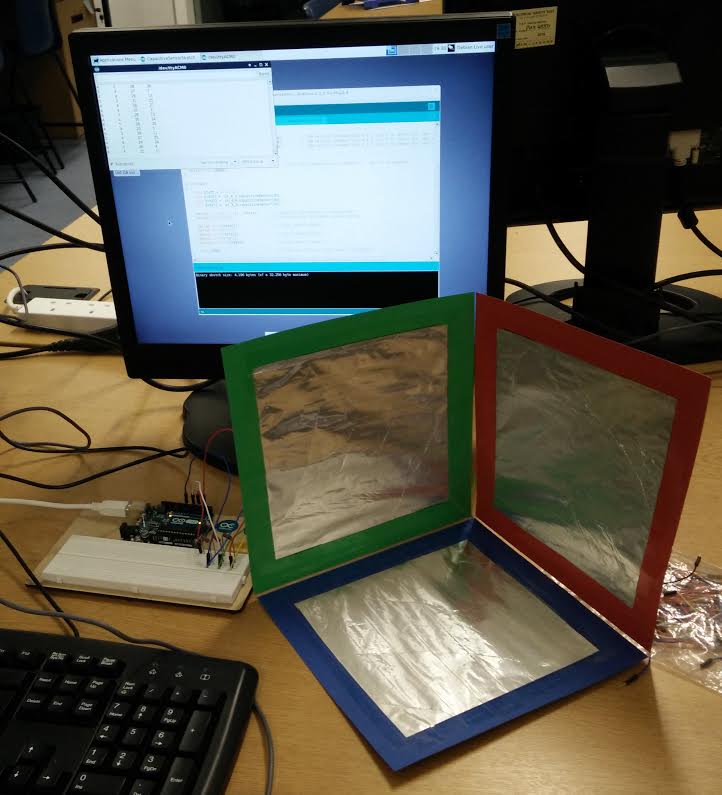

Trialling Capacitive Sensing

Visiting the Portland Works

Playing with the PiGlow

Steel etching experiments

Juggling club teepee clip

Visiting Researchers

Sheffield Maker Day 2014 – With SHHM

Once again the Sheffield hardware hackers and Makers attended the Maker Day 2014, but only this time it was hosted in The Yorkshire arts space just opposite of Access Space.

February the 15th build day

2013

November The 25th Meet Up

This meet up we had many things to be discuss. Some of the things that we went through…

Sheffield Hardware Hackers

The Sheffield Hardware Hackers and Makers group have a build day on the Saturday of each month, and a evening meet up on the last Monday of every month. There will be no meet ups or build days in August because Acsess space is closed. Normal meet ups and build days will return in September.

Noah’s Ark Repair

My 15-month-old son has a rather nice-looking Noah’s Ark, given to him by his grandpa for his first birthday. We look forward to using it to teach him about God’s preservation of Noah and His promise to the world, as signified by a rainbow.

Latest meet up

This week on the 25th of march was our third meet up of the year. This month a number of things took place.

– Whats been going on/admin

– What projects people are getting involved in

– Set up of mendel 90 3D printer and installation of software

– 3D Printing

– Laser cutting

This post by SHHM member

This post by SHHM member